Properly aligned tracks are essential for your garage door’s smooth, secure operation. Misaligned tracks can cause many issues, from making it hard to use to wearing out components too quickly. This guide will show you how to correct misalignment, get the tools you need, and adjust your garage door tracks step by step.

This piece will give you the information and confidence you need, whether you like to do things yourself or just want to know how they work. Remember that if you ever feel unsure about something, please call the experts at Mehrs Garage Doors. They’ve been helping people in St. George, Utah, and the surrounding areas for over 40 years.

Recognizing the signs of misalignment before you begin fixing your garage door tracks is essential.

Complex operation: A sign often seen is a door that is hard to open or close. If you need help lifting your door by hand or if your garage door opener is working harder than usual, it could mean that your tracks need to be put in line.

Uneven gaps: Another sign is gaps that need to be level between the door and the frame. Examine the space on both sides of your door between the frame and the door when it is closed. If the gap is more prominent on one side than the other, your tracks need to be put in the right place. This can also cause the door to rub against the frame when it moves, damaging it over time.

Unusual noises: Your garage door may make strange noises as it works. Track misalignment can be characterized by grinding, scraping, or popping sounds. These sounds are usually caused by rollers getting stuck or slipping as they move along the tracks.

Worn or damaged components: At Mehrs Garage Doors, we suggest you look closely at the rollers and hinges of your garage door while checking for misalignment. Track damage can result from these components becoming misaligned or worn over time. On the rollers, look for flat spots or hinges that are coming loose. These are all signs of too much wear. Before trying to adjust your tracks, it is best to replace any damaged components.

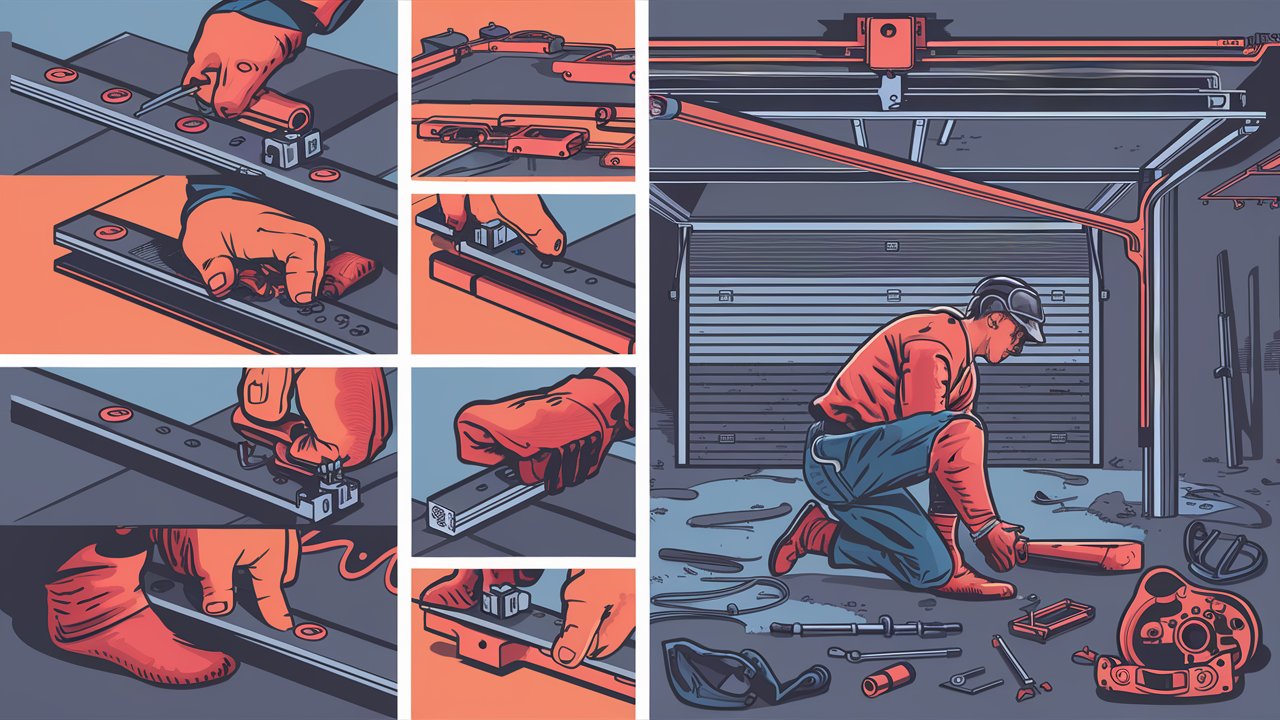

The right tools and materials are essential for a smooth and quick process when fixing your garage door tracks. You’ll need a wrench or a socket set to loosen and tighten the bolts that hold your track brackets in place. A carpenter’s level is essential to ensure that your tracks are level and adequately lined with one another.

We at Mehrs Garage Doors advise using a plastic hammer to tap your tracks into place carefully without causing any damage. Locking tools, called vice grips, can hold your garage door in place while you work on the tracks.

A strong stepladder will let you safely reach the higher parts of your garage door tracks. Wearing work gloves and safety glasses will protect your hands from pinch points and sharp edges while protecting your eyes from dust and debris.

Before you can adjust your tracks, you might need to replace some components. We at Mehrs Garage Doors recommend replacing worn or damaged rollers with high-quality, nylon-coated rollers for smooth and quiet operation. Replacing loose or damaged hinges can also ensure a secure link between your door panels and the tracks.

Aligning the garage door’s vertical tracks is the final step in fixing your garage door. This ensures your door goes smoothly along its path without rubbing or getting stuck.

The first thing we need to do is check how the vertical tracks are currently lined up. From inside your garage, stand up and look at the tracks from different points of view. They should go straight up at the bend where the straight tracks meet the floor. Any bending or misalignment can be seen with the naked eye.

Using a tape measure, we ensure the tracks are straight across from one another. To find the distance between the tracks, start at floor level and measure again at waist height. Finally, measure at the top where the tracks bend. The measurements should always be the same. We must adjust if they are not. Let’s adjust those now:

The lag bolts holding the track brackets to the wall must be loosened. Take them off partially, but not all the way—just enough to let you move. To get the track in the right place, gently push or pull it. A level can be used to ensure that it is perfectly vertical. Once the track looks straight, half-tighten the lag bolts. We’ll tighten them up one last time later. Do the same thing with the other vertical track.

At Mehrs Garage Doors, we use a wooden hammer to make minor adjustments. No damage is done when you gently tap the tracks to get them in the right place. How to do it:

To protect the track, place a block of wood against it. To make minor adjustments, hammer the wood block with a rubber mallet. Use the level and tape measure to check your work often. We want the tracks to be perfectly vertical and aligned. It may take time and several adjustments, but it will be worth it.

Once both tracks are lined up, double-check your measurements one last time. At the bottom, middle, and top, make sure the tracks are all the same distance apart. If everything looks good, we can fully tighten all the lag bolts.

A word of caution: call a professional if you notice significant misalignment or damage to the tracks. It is better to replace tracks that have been badly bent or dented rather than adjust them.

When we align the vertical tracks, we move on to the horizontal ones. These must be level for your garage door to work safely and quickly. Allow us to begin by measuring:

At the point where each horizontal track meets the vertical track, use a tape measure to check its height. Once more, measure at the middle and back of each horizontal track. Check out these measurements. At every point, they should be the same for both tracks. Please feel free to make mistakes. That’s why we’re here. It’s essential to fix any differences in height, no matter how small they are.

Take the bolts off of the brackets for the track hangers. In most garages, these are near the ceiling or on the back wall. To raise the track that is too low to the same height as the other track, gently lift it. This step might need some help. Lower the track slowly until it is the right height. To ensure that the tracks are entirely straight, use a level.

Adjust until the bubble is in the center after placing it on the track. Make sure both tracks are the same height and angle. As you return to the garage, they should drop down about 1/4 inch for every 10 feet of track. Remember to be patient about how minor adjustments can significantly alter your garage door works.

Remember to check all of the measurements one more time. On the track hanger brackets, tighten all of the bolts. Ensure they fit snugly, but keep them tight enough, or the brackets or tracks could get damaged. The lag screws that secure the brackets to the ceiling or wall should be examined. If you need to, tighten these. To ensure that each closure is secure, give it one last check.

Once more, look over the whole track system to see if any areas need more work. We ensure your garage door works quickly and safely by correctly leveling and securing your horizontal tracks. This step is essential to avoid issues like the door going off track or putting too much stress on the opener.

Remember to call us, the professionals at Mehrs Garage Doors, if you are unhappy working at height or if your garage has a particularly complicated track system. Your safety and the garage door’s proper functioning are the most important.

Pulling the emergency release cord, you can disconnect the opener. This is often a red line attached to the cart. Lift the door halfway manually. Garage door weights can be heavy, so use caution. Do not use your back to lift. Instead, use your legs. The door should stay in place on its own. This shows that the spring tension is correct. The springs must be adjusted if they fall or rise.

Do not try to adjust torsion springs yourself; it is dangerous and should only be done by a professional. Make sure that the movement is smooth across the whole range of motion. The door should be able to move smoothly and not get stuck or stop at any time.

Listen for sounds that don’t sound right, like grinding or squeaking. These could be signs of issues with the rollers, hinges, or tracks that require lubrication or replacement. Check the door from different heights. If it stops moving at any point, it should stay where it is.

Close the door all the way. Make sure it’s sitting down flat on the ground. Pulling the release cord toward the door will join the opener again. You might lift the door slightly to get the trolley to enter again. Make sure that the trolley is back in contact with the opener frame. The trolley should lock into place, and you should hear or see a click. To make sure the door is firmly attached to the opener, gently pull it down.

Use the control or the button on the wall to repeatedly open and close the door. Watch how the door moves inside and outside the garage if you can. Look for smooth, quiet function. The door should move smoothly without jerking or stopping. Make sure the door can open and close all the way. It should adequately seal when closed and leave no space at all when open.

Recheck track alignment and make any necessary adjustments if issues continue. Pay close attention to places where the door seems to stick or make noise. Check the door’s safety measures, such as the auto-reverse feature. Ensure that the door turns around when it hits the barrier by placing a piece of wood on the ground where it closes.

Talk to a professional expert about problems that won’t go away or need spring adjustments. Experts should be consulted for problems involving spring tension, wire alignment, or complicated opener issues. If everything else is in order, lubricate moving parts like hinges, springs, and rollers with silicone-based lube to keep the operation smooth.

We suggest checking your garage door system every three to six months. Check the rollers for wear and look for lumps or bends in the tracks. Clean them with a wet cloth. Check the hinges for metal wear or screws that aren’t tight. Make sure that no brackets or bolts are loose. Check the wires for fraying and the weatherstripping for damage. This regular check ensures smooth function and helps avoid common issues.

If you do this once a year, your garage door will last longer. Use white lithium grease or a silicone-based lube to keep rollers, hinges, and tension springs in good shape. Use little—a few drops on each moving part is enough.

Wipe off the extra to prevent dust from building up. If you grease the tracks, dirt can stick to them, and the rollers slip. You should use a dry lube to keep the lock mechanism from freezing in cold weather.

Some garage door fixes can only be done by a professional. Due to the open risks and the specialized knowledge needed, torsion spring adjustments, wire replacements, and opener problems are best handled by experts.

To identify possible issues early, think about having a professional check done every year. The cost of repair or replacement will depend on how old or badly damaged your door is. A professional can help you decide. Any quick changes in the door’s work, like loud noises or fast movements, should be reported immediately to a professional to ensure safety and proper function.

The essential steps for track misalignment have been covered: detecting misalignment, preparing the door, aligning vertical tracks, leveling horizontal tracks, and checking door balance. This process is extensive, but the garage door must work properly. Throughout these adjustments, keep in mind that safety comes first.

Correctly oriented tracks ensure smooth operation, lessen components’ wear, and increase productivity. They also improve safety by keeping doors from breaking and making the system last longer. Maintaining your tracks regularly is a small cost that will pay off in improved performance, safety, and longevity of your garage door system.

Noises like squeaking or grinding, gaps between the door and tracks that can be seen, the door sticking or catching while it’s being used, and uneven movement when opening or closing are all common signs.

If you have significant misalignments spring issues, or are unhappy with the process, it’s best to hire a professional. However, you can frequently make minor adjustments. Your top concern should always be safety.

You should check and adjust your tracks every three to six months. With regular use, tracks may need to be adjusted every one to two years.

You need a level, wrench set, pliers, rubber mallet, and measuring tape. Safety glasses and job gloves are also required to protect you.

Yes, premature wear on rollers, hinges, and the door itself can be caused by uneven tracks. They may also put extra stress on the garage door opener, which could make it last less long.

Copyright © 2025 Mehrs Garage Doors. All Rights Reserved.

Web Development By The Active Media.